Three Demensional Printing

As our society is advancing at an accelerated rate.

Technology has advanced from phones that were 5 inch wide

but in just 10 years, it is now thinner than 1 centimeter.

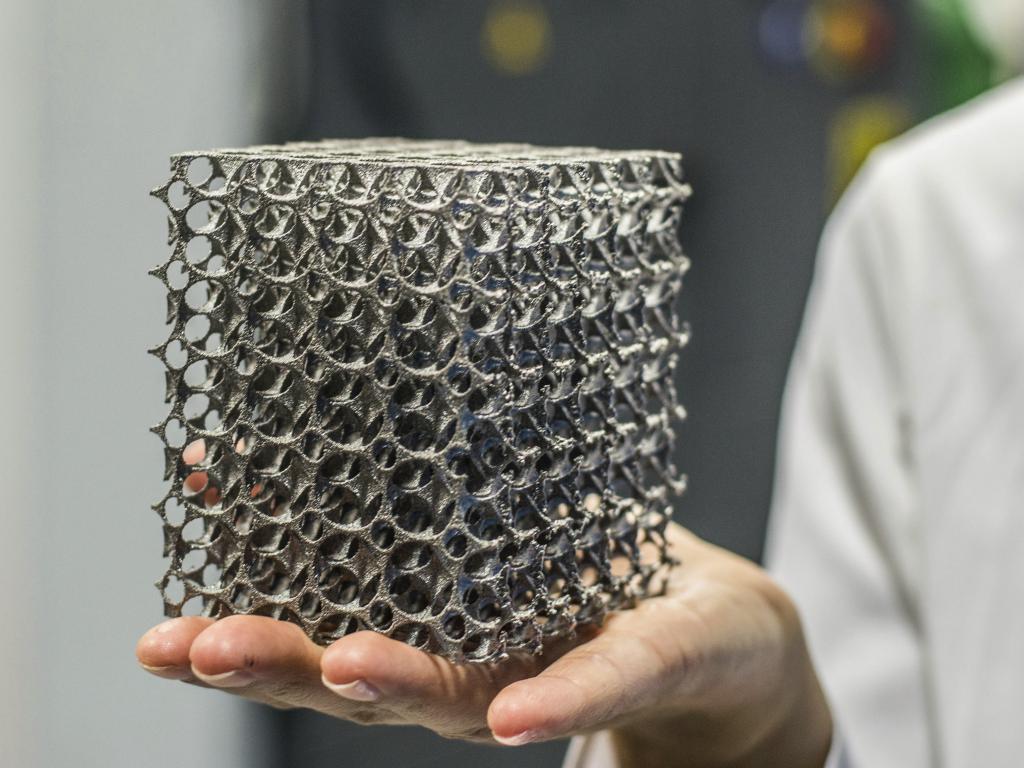

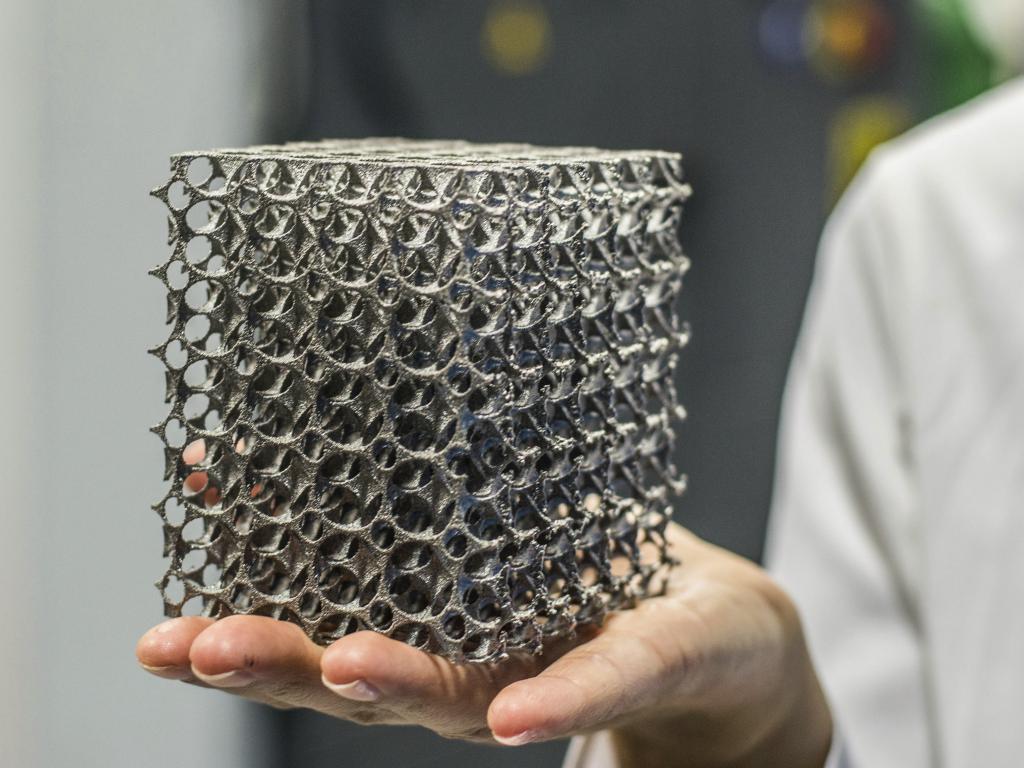

Three demensional printing started off as small plastic objects

being printed off but now, there are three demensional objects

that could be made of metal.

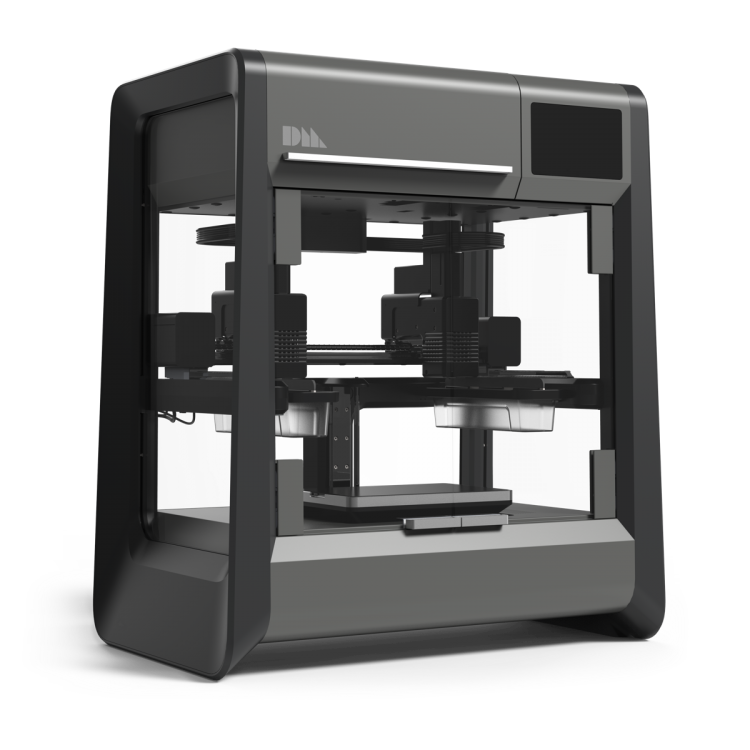

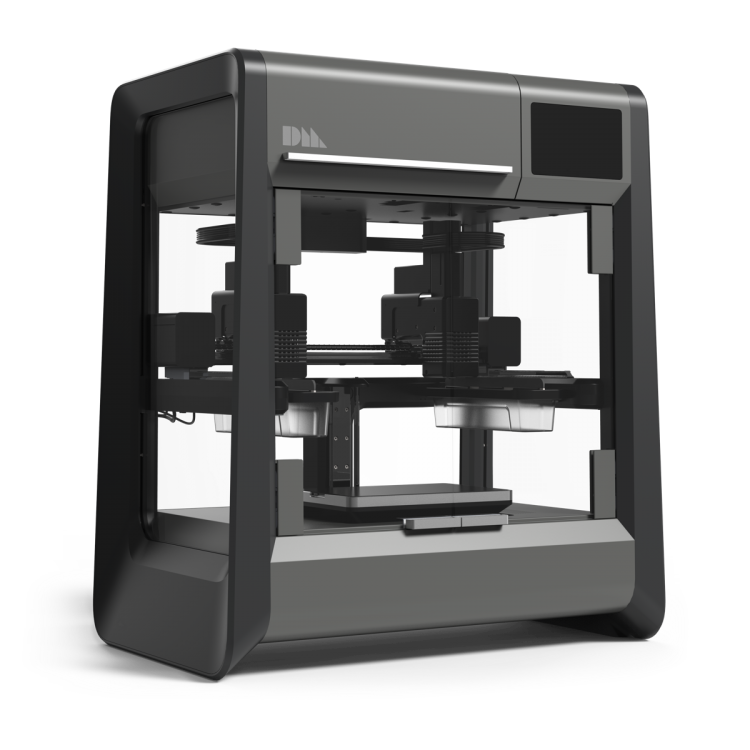

How it works: Metal 3D Printing is a laser-based technology that uses powdered metals.

A high-powered laser selectively binds together particles

on the powder bed while the machine distributes even layers of metallic powder.

Support structures are automatically generated and built simultaneously in the same material,

and are later manually removed. Once complete, the part undergoes heat treatment.

What 3D printing is doing for us today: It allows for the direct

manufacturing of complex end-use parts and facilitates tooling for conventional

manufacturing technologies, reducing costs and lead times. This technology is

also known as Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM).

Companies such as GE are already making turbines with 3D printing with metal which

is about the same quality as typical production.

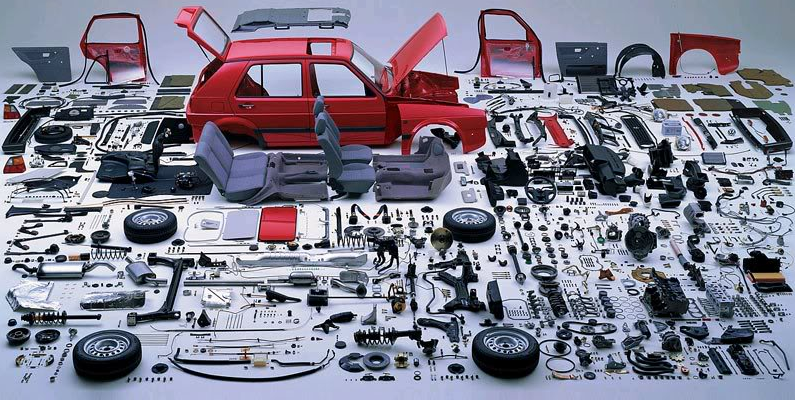

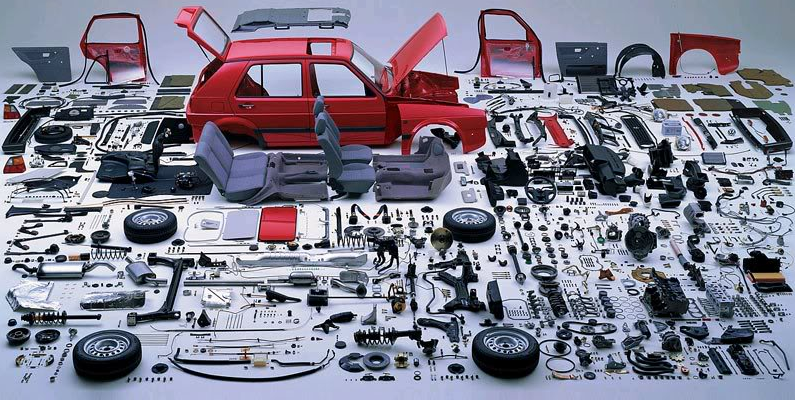

One area of growth in the 3-D printing arena is replacement parts production.

Need a new screw for your laptop? A new gear for your heirloom grandfather clock? A new

piston for your car?

Instead of trying to track down the part, pay for shipping, and waiting weeks for its arrival,

you’ll just be able to print it out and go. Mechanics will keep specs for every part of every car

ever sold in a database and print out whatever they need immediately with no difficulty.

While it would save time and money for any part, it’s a particular boon for restoration

jobs of all kinds where the original parts are extremely difficult to find or may not

even exist anymore.